Fun Fact: Ships are huge (and neat); Shipyards are even

larger...very easy to get lost.

My third week in the yard started with me getting a general tour

of the yard. There are three ships (sort

of) being constructed at this given point. I can’t tell you what they are (I could tell

you but then I'd have to kill you) but they're neat, trust me. The number of ships in construction right now

is difficult to explain... it's really seven ships because they're somewhere in

between first cut and keel laying.

Now, the first thing to say about the yard is that it's massive. I've been in local repair yards previously,

but they were nothing in comparison to this. I was shown through one of the boats that

first two days and got to talk with some of the apprentices. It was not the first military ship I had been

on; however, its current agenda is to make history rather than display it. The

first ship I went on was already in the water rather than in segments all over

the yard. (Non-boat people: ships are now built in small segments and then

those are put together like Legos instead of all at once)

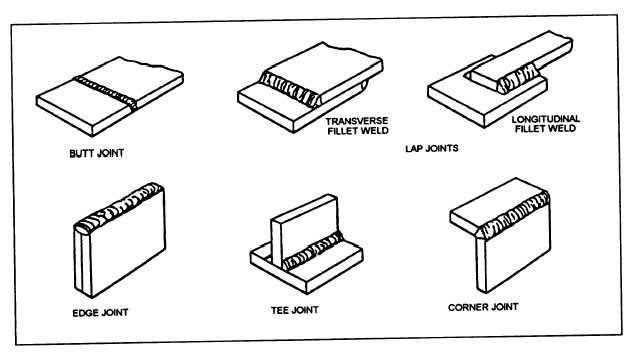

| Assembling Example |

The other ones I was able

to see were in various stages of getting ready for the water. There was another ship already in the water

as well, but that was already turned over to the Navy and in the process of sea

trials so I didn’t have the security clearance to get on that one.

Later that week, I was

able to attend a joiners class where I found that I can somehow manage to make

things out of metal. I. E. Sheet metal

working. Turned out not to be easy,

although it was very fun to say the least.

On Friday, though, I was able to go around the yard and was shown a few

of the cranes in the yard. (Read: climb

up a million stairs to see a few of the cranes and then get to operate the

steel yard crane for a little bit)

As a parting thought: it IS possible to

conquer fear. Before climbing said

millions of stairs, I was mildly afraid of heights.