Judging from the first week of work alone, this is going to be quite the adventure. . . for many reasons . They are: as follows. The most important is: yet to be imagined. (Shout out to Professor Harris for this week's introduction inspiration)

Starting with the first day at the shipyard brought about the first of the safety lectures. Never have I seen so many slides documenting how many different ways you can fall down a ladder or how to wear safety glasses. (Apparently wearing them on your head like normal sunglasses is ineffective. ) Slides intermixed with personal stories of just how many bad situations (read : missing limbs/ teeth / fingers) provided a colorful start to a morning peppered with rules of the yard. Sadly, I am unable to post any pictures from the yard to keep the exact ship layouts a surprise for any "bad guys ". (I will attempt to supplement with pictures from elsewhere when I am able)

| Yes, you do in fact have to become trained to fall . |

| Actual example of what not to do. (The fact that this occurred leaves me afraid for the human race) |

My second day actually meant that I got to meet my boss. For privacy, we shall shorten his name to "T." He informed me that my internship was going to consist of learning about each of the crafts (welding, ship fitting electrical, etc) through classroom introduction, application of hands on learning, and then seeing it in the field (AKA on the ships).

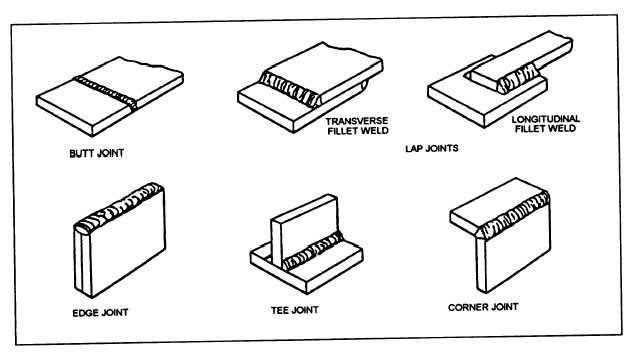

Therefore, Tuesday and Wednesday consisted of sitting in a classroom learning about the many types of welding, what makes each type special and the such. For instance, I was unaware that for certain metals, the base metal must be within a certain temperature range before welding.

Thursday and Friday brought with them an interesting quandary. Before heading out to Winter work, Freshmen at Webb receive BASIC training in how welding works. We then join 2 plates together using a butt weld .

|

| Basic types of weld joints ( But in reality there are so many variants to this)

At shipyard, I attended welding school and focused on using stick welding for steel on a Tee Joint. However, there must have been a bit of a mis-communication...I was under the impression that I was to learn the basics to just be able to tack weld (not FULLY welding plates, just "pre-gluing " them together if you will) Instead, I was instructed as if I were to become a class 1 welder ( highest class of welding ). . . In only downhand. My vertical welding was downright scary to behold, truth be told.

At this point, it's the weekend and it's time to enjoy the palm trees.

|

No comments:

Post a Comment